The Importance of Proper Boiler Piping

Boiler piping is the backbone of any heating system, responsible for effectively distributing hot water or steam throughout a building. Designing and installing this network of pipes, valves, and fittings is a critical task that can make or break the efficiency and longevity of your heating system. As a seasoned expert in plumbing and heating services, I’ll provide you with practical tips and in-depth insights to help you optimize the flow and circulation of your boiler piping system.

Understanding the Role of Piping in Heating Systems

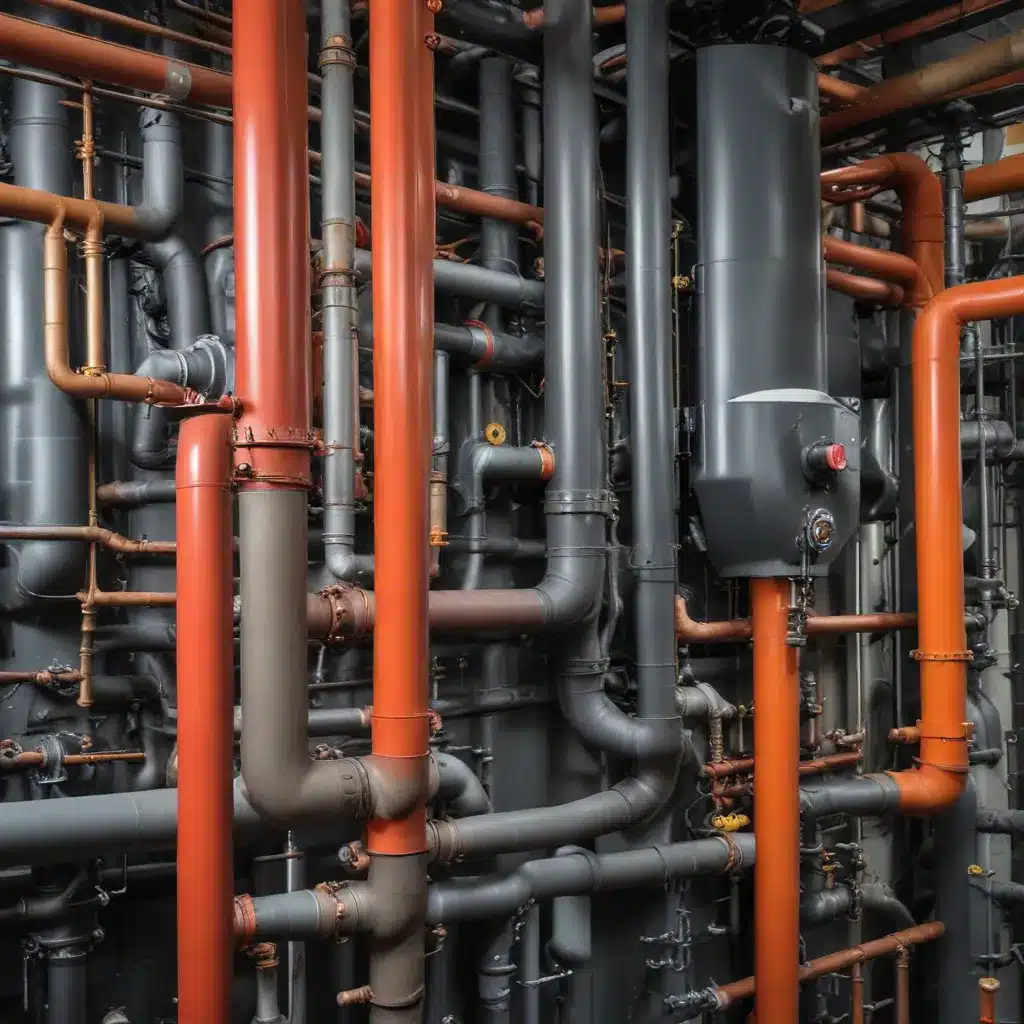

Piping is more than just a means of transporting fluids; it’s the facility’s circulatory system, responsible for moving essential materials – water, chemicals, gases, or other substances – where they’re needed, quickly and safely. Proper piping design and engineering can significantly impact the overall performance, maintenance requirements, and lifespan of your heating system.

Optimizing Flow and Circulation

The primary goals of effective boiler piping design are to optimize fluid flow and ensure even circulation throughout the system. This means minimizing resistance, eliminating bottlenecks, and promoting balanced distribution of heat. By achieving these objectives, you can maximize the efficiency of your heating system, reduce energy consumption, and extend the lifespan of your boiler and associated components.

Considering System Complexity

Boiler piping systems are not simple, isolated components; they are part of a vast network of interconnected and independent systems, including process pipes, valves, and fittings that transport fluids and gases throughout the entire facility. Successful boiler piping design requires close collaboration between various engineering disciplines to ensure the system’s overall functionality and integration.

Key Principles of Boiler Piping Design

When it comes to optimizing boiler piping design, there are several crucial principles to consider:

1. Flow Optimization

Ensuring efficient fluid flow is paramount. This involves selecting the appropriate pipe sizes, minimizing unnecessary bends and fittings, and maintaining consistent pipe diameters throughout the system. By reducing resistance and turbulence, you can maximize the system’s flow rate and improve heat distribution.

2. Balanced Circulation

Achieving even heat circulation is essential for maintaining consistent temperatures and preventing hot or cold spots. This can be accomplished through proper pipe sizing, strategic placement of circulators or pumps, and the incorporation of balancing valves or hydraulic separators.

3. System Integration

Boiler piping design must consider the integration of the entire heating system, including the boiler, heat emitters (e.g., radiators, baseboard heaters), and any additional components such as expansion tanks or air separators. Careful coordination between these elements ensures optimal performance and functionality.

4. Safety and Longevity

Designing a safe and durable boiler piping system is crucial. This includes selecting appropriate materials, incorporating adequate expansion capabilities, and ensuring proper insulation to prevent heat loss and potential damage. By prioritizing safety and longevity, you can minimize the risk of leaks, corrosion, or other issues that could compromise the system’s performance.

Practical Tips for Boiler Piping Design

Now, let’s dive into some practical tips to help you optimize the flow and circulation of your boiler piping system:

1. Pipe Sizing and Layout

- Select pipe sizes that match the boiler’s output and the system’s heating load requirements.

- Minimize the number of bends and fittings to reduce resistance and turbulence.

- Ensure consistent pipe diameters throughout the system to promote even flow.

- Strategically position pipes to minimize overall length and facilitate easy access for maintenance.

2. Circulation and Balancing

- Incorporate high-efficiency circulators or pumps to move the heated fluid efficiently.

- Install balancing valves at key locations to adjust and maintain proper flow rates.

- Consider the use of a hydraulic separator to decouple the primary and secondary circuits, improving circulation.

- Regularly monitor and adjust the system to ensure optimal flow and heat distribution.

3. System Integration

- Coordinate the boiler piping design with the selection and placement of heat emitters.

- Integrate expansion tanks, air separators, and other components to maintain system integrity and performance.

- Ensure compatibility between all system components to prevent issues like corrosion or scaling.

4. Safety and Longevity

- Select durable, corrosion-resistant materials for the piping and fittings.

- Provide adequate expansion capabilities to accommodate thermal expansion and prevent stress on the system.

- Insulate the piping system to minimize heat loss and protect against potential damage.

- Implement regular maintenance protocols to identify and address any issues before they escalate.

By following these principles and practical tips, you can design a boiler piping system that optimizes flow, ensures balanced circulation, and promotes long-term reliability and efficiency. At DD Plumbing and Heating, we take pride in our expertise in providing top-notch plumbing and heating services, including the design and installation of boiler piping systems that meet the highest standards of performance and durability.

The Future of Boiler Piping Design

As technology and industry trends continue to evolve, the future of boiler piping design is also shaping up to be more advanced and sustainable. At DD Plumbing and Heating, we stay at the forefront of these developments, incorporating the latest innovations and best practices to deliver the most efficient and reliable heating solutions for our clients.

Some of the emerging trends in boiler piping design include:

-

Modular Construction Techniques: The integration of modular components and prefabricated piping systems can streamline the installation process, reduce on-site labor, and improve overall system quality.

-

Advanced Materials and Coatings: The use of more durable, corrosion-resistant materials and specialized coatings can enhance the longevity and performance of boiler piping systems.

-

Digitalization and IoT Integration: The incorporation of smart sensors, remote monitoring, and internet-connected controls can provide real-time data and enable predictive maintenance, optimizing system efficiency and reducing downtime.

-

Sustainability and Green Solutions: Eco-friendly design approaches, such as the use of renewable energy sources, waste heat recovery, and energy-efficient components, can contribute to the overall sustainability of boiler piping systems.

-

Robotics and Automation: The integration of robotic and automated technologies can improve the precision and consistency of boiler piping installation, enhance safety, and minimize the risk of human error.

By staying up-to-date with these trends and continually investing in research and development, DD Plumbing and Heating is committed to delivering state-of-the-art boiler piping solutions that meet the evolving needs of our clients. Our experienced team of plumbing and heating experts is dedicated to providing innovative, sustainable, and high-performance systems that optimize flow, ensure balanced circulation, and promote long-term reliability.

If you’re planning a new heating system installation or looking to upgrade your existing boiler piping, we encourage you to reach out to the professionals at DD Plumbing and Heating. Our comprehensive services and commitment to excellence can help you achieve the optimal performance, energy efficiency, and comfort you deserve. Contact us today to discuss your project and let us guide you towards the perfect boiler piping solution.