Understanding Boiler Exhaust and Venting Essentials

Boilers are essential heating appliances found in many homes and commercial buildings, providing warmth and hot water. However, the safe and efficient operation of a boiler relies heavily on proper exhaust and venting systems. Improper venting can lead to serious safety hazards, such as carbon monoxide buildup, fire risks, and even respiratory issues for building occupants. As a seasoned plumber and heating expert, I’ll delve into the critical aspects of boiler exhaust and venting, helping you ensure your system meets all necessary safety and code requirements.

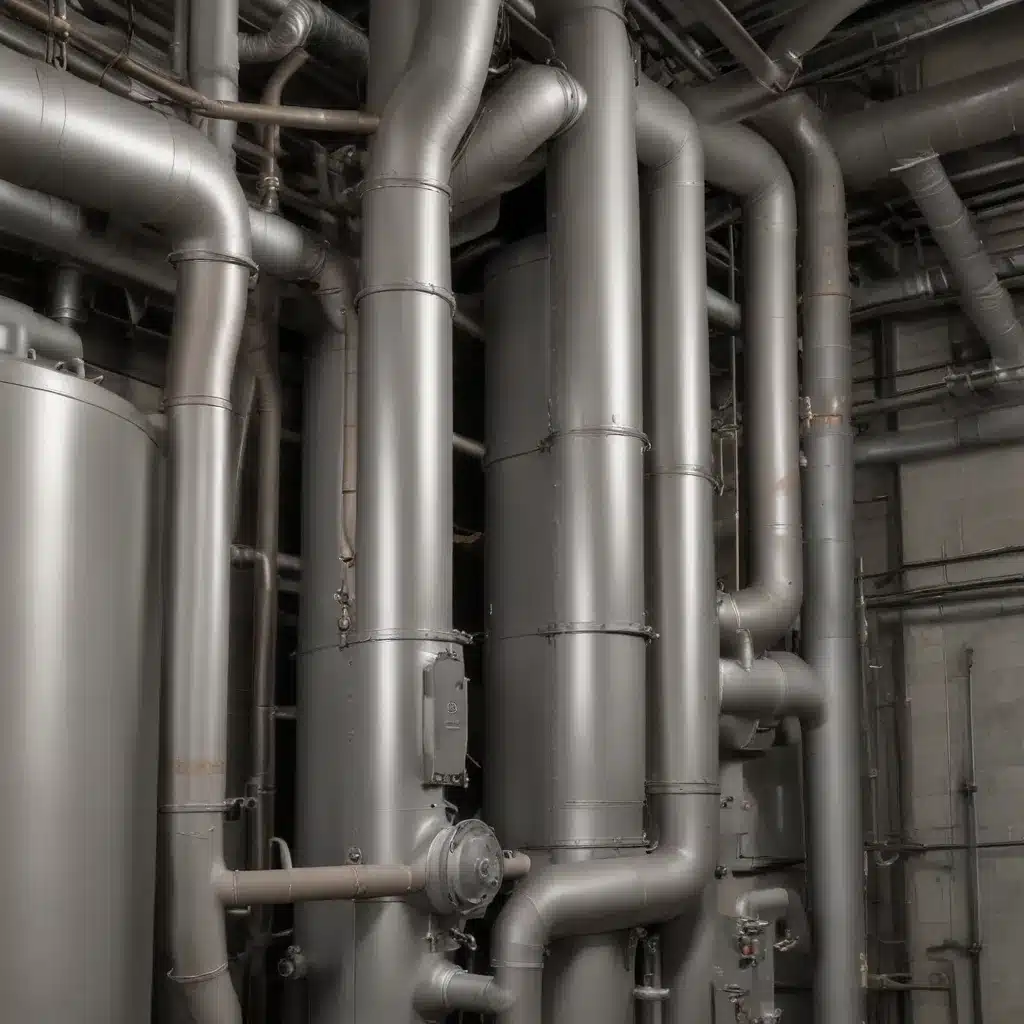

Boiler Exhaust and Venting Basics

The exhaust and venting system for a boiler serves two primary functions: 1) Removing dangerous combustion byproducts, such as carbon monoxide, and 2) Providing adequate airflow to the boiler for efficient combustion. This system typically consists of a vent or flue that carries the exhaust gases outside the building, as well as air intake vents that allow fresh air to enter the combustion chamber.

It’s crucial to understand that boiler exhaust and venting requirements can vary depending on the type of boiler, the fuel source, and the local building codes in your area. For example, high-efficiency condensing boilers may require different venting materials and configurations compared to traditional non-condensing boilers. Proper sizing, materials, and installation of the venting system are essential to ensure safe and reliable operation.

Navigating Boiler Exhaust and Venting Codes and Regulations

Boiler exhaust and venting systems are subject to a variety of safety codes and regulations, which can differ depending on your location. It’s important to familiarize yourself with the applicable codes in your area to ensure compliance. Some key considerations include:

-

Venting Material Requirements: Boiler vents may need to be constructed from specific materials, such as stainless steel, aluminum, or polypropylene, depending on the boiler type and local codes. Proper material selection is crucial for withstanding high temperatures and preventing corrosion.

-

Venting Diameter and Slope: The diameter of the vent pipe must be correctly sized to accommodate the boiler’s rated output and ensure adequate airflow. Additionally, the vent must be installed with a slight upward slope to facilitate the proper flow of exhaust gases.

-

Vent Termination Requirements: Boiler vents must be terminated in a specific manner, often with a specified minimum height above the roof or a minimum distance from windows, doors, or other building openings. These requirements help prevent the re-entry of exhaust gases into the building.

-

Combustion Air Supply: Boilers require a steady supply of fresh air for efficient combustion. Building codes often dictate the size, location, and configuration of air intake vents to ensure a sufficient air supply.

-

Condensate Drainage: In the case of high-efficiency condensing boilers, the venting system must provide a way to safely remove the acidic condensate that forms during the combustion process.

-

Inspection and Maintenance: Regular inspections and maintenance of the boiler exhaust and venting system are essential to ensure continued safe and efficient operation. Building codes may require specific inspection schedules or procedures.

By familiarizing yourself with the relevant codes and regulations in your area, you can ensure that your boiler’s exhaust and venting system is installed and maintained in compliance with all safety and performance standards.

Ensuring Proper Boiler Exhaust and Venting Installation

Proper installation of the boiler exhaust and venting system is crucial for its safe and efficient operation. Here are some key considerations:

Vent Pipe Selection and Sizing

The selection of the appropriate vent pipe material and diameter is essential. As mentioned earlier, the vent pipe must be compatible with the boiler type and local building codes. Factors such as the boiler’s BTU (British Thermal Unit) rating, the length and configuration of the vent run, and the altitude of the installation site all play a role in determining the correct vent pipe size.

https://apps.leg.wa.gov/wac/default.aspx?cite=51-52-0403

For example, the Washington Administrative Code (WAC) 51-52-0403 specifies that the vent pipe diameter for a gas-fired boiler should be no less than the size of the boiler’s flue collar. It also provides guidelines for the maximum vent length and the number of elbows allowed, based on the vent pipe diameter and boiler input rating.

When selecting the vent pipe, it’s crucial to choose a material that can withstand high temperatures and corrosive condensate, such as stainless steel or polypropylene. Improper material selection can lead to premature failure of the vent system, resulting in safety hazards and potential code violations.

Vent Pipe Installation and Routing

The installation and routing of the vent pipe also play a crucial role in ensuring proper boiler exhaust and venting. The vent pipe should be installed with a slight upward slope (typically 1/4 inch per foot) to facilitate the flow of exhaust gases. Additionally, the vent pipe should be properly supported to prevent sagging or displacement, which could impede the flow of exhaust gases.

The routing of the vent pipe should also consider the location of the boiler in relation to the building’s exterior. The vent termination must be positioned in accordance with local building codes, which may specify minimum distances from windows, doors, air intakes, and other building features.

http://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.57

It’s important to note that the Occupational Safety and Health Administration (OSHA) has regulations (1926.57) regarding the placement of exhaust vents to ensure that they do not pose a hazard to workers or building occupants. Compliance with these regulations is essential for maintaining a safe work environment.

Combustion Air Supply Considerations

Proper combustion air supply is critical for the efficient and safe operation of a boiler. Building codes often require the installation of dedicated combustion air intake vents to ensure a steady supply of fresh air to the boiler. These vents may need to be sized based on the boiler’s input rating and the specific requirements of the local building code.

In some cases, the boiler may be able to draw combustion air directly from the space where it is installed, known as “direct vent” or “sealed combustion” configuration. This can be a more energy-efficient option, as it reduces the amount of conditioned air being drawn from the living space. However, the specific requirements for this type of installation must be carefully considered and followed to ensure compliance with safety standards.

Condensate Drainage

For high-efficiency condensing boilers, the venting system must include a means of properly draining the acidic condensate that forms during the combustion process. This may involve the installation of a condensate trap, neutralizer, or direct connection to a drainage system.

Improper condensate drainage can lead to corrosion of the vent system, as well as potential water damage to the building. Ensuring the correct installation and maintenance of the condensate drainage system is essential for the long-term reliability and safety of the boiler.

The Ohio Mechanical Code, for example, provides specific requirements for the installation and maintenance of condensate drainage systems for heating appliances, including boilers. Following these guidelines can help ensure compliance and prevent potential issues.

By paying close attention to vent pipe selection, installation, combustion air supply, and condensate drainage, you can help ensure that the boiler exhaust and venting system is properly installed and meets all relevant safety and code requirements.

Maintaining Boiler Exhaust and Venting Systems

Regular maintenance and inspection of the boiler exhaust and venting system are crucial for ensuring its continued safe and efficient operation. Here are some key steps to consider:

Periodic Inspections

Regularly scheduled inspections of the boiler exhaust and venting system can help identify potential issues before they become serious problems. During these inspections, you should check for:

- Obstructions: Ensure that the vent pipe is clear of any blockages, such as bird nests, debris, or corrosion buildup.

- Proper Slope: Verify that the vent pipe is installed with the correct upward slope to facilitate the flow of exhaust gases.

- Vent Termination: Confirm that the vent termination meets the required clearances from windows, doors, and other building features.

- Corrosion: Inspect the vent pipe and connections for any signs of corrosion, which can compromise the integrity of the system.

- Condensate Drainage: Ensure that the condensate drainage system is functioning correctly and that the condensate is being properly disposed of or neutralized.

Regular inspections can help identify and address issues before they escalate, ultimately ensuring the safe and efficient operation of the boiler.

Cleaning and Maintenance

In addition to inspections, regular cleaning and maintenance of the boiler exhaust and venting system are essential. This may include:

- Vent Pipe Cleaning: Removing any buildup of soot, debris, or corrosion from the interior of the vent pipe to maintain proper airflow.

- Vent Termination Cleaning: Clearing the vent termination of any obstructions, such as leaves, twigs, or snow, to ensure proper exhaust gas discharge.

- Combustion Air Intake Cleaning: Ensuring that the combustion air intake vents are free of any obstructions or debris, allowing for adequate airflow.

- Condensate System Maintenance: Checking and cleaning the condensate drainage system, including the trap, neutralizer, and any connection to a drainage system.

Regularly performing these maintenance tasks can help extend the lifespan of the boiler exhaust and venting system, reduce the risk of issues, and ensure the continued safe and efficient operation of the boiler.

Addressing Issues and Repairs

Despite regular maintenance, issues may still arise with the boiler exhaust and venting system. Some common problems that may require attention include:

- Vent Pipe Damage: Cracks, holes, or other physical damage to the vent pipe that can compromise its integrity and lead to exhaust gas leaks.

- Vent Termination Problems: Blockages, corrosion, or improper installation at the vent termination that can impede the proper discharge of exhaust gases.

- Condensate Drainage Issues: Clogs, leaks, or other problems with the condensate drainage system that can lead to water damage or corrosion.

- Insufficient Combustion Air: Obstructions or sizing issues with the combustion air intake vents that can affect the boiler’s operation and efficiency.

If any of these issues are identified, it’s essential to address them promptly to ensure the continued safe and reliable operation of the boiler. Depending on the severity of the problem, repairs may range from simple maintenance tasks to more complex system replacements. Always consult with a qualified and experienced plumber or heating specialist to ensure that any necessary repairs are carried out correctly and in compliance with all applicable safety standards and building codes.

By staying vigilant with regular inspections, maintenance, and prompt issue resolution, you can help ensure that your boiler’s exhaust and venting system continues to operate safely and effectively, providing reliable heating and hot water for your home or business.

Conclusion: Prioritizing Boiler Exhaust and Venting Safety

Proper boiler exhaust and venting is a critical component of any heating system, ensuring the safe and efficient operation of the boiler. By understanding the essential elements of boiler exhaust and venting, familiarizing yourself with the relevant codes and regulations, and implementing best practices for installation and maintenance, you can help your customers maintain a safe and comfortable living or working environment.

At DD Plumbing and Heating, we prioritize the safety and well-being of our clients. Our team of experienced plumbers and heating specialists is dedicated to providing comprehensive solutions that meet all necessary safety and code requirements. If you have any concerns or questions about your boiler’s exhaust and venting system, don’t hesitate to reach out to us. We’re here to help you navigate the complexities of boiler maintenance and ensure your heating system continues to operate at its best.