The Importance of Boiler Combustion Optimization

As a seasoned expert in plumbing and heating services, I understand the critical role that boiler combustion optimization plays in enhancing system performance and ensuring safety. Boilers are the backbone of many industrial, commercial, and residential heating systems, providing essential heat and power. However, without proper combustion optimization, these vital appliances can become inefficient, unreliable, and even hazardous.

In this comprehensive guide, we’ll explore the intricacies of boiler combustion optimization, delving into practical tips, in-depth insights, and state-of-the-art solutions to help you maximize the efficiency, safety, and longevity of your heating systems.

Understanding Boiler Combustion Dynamics

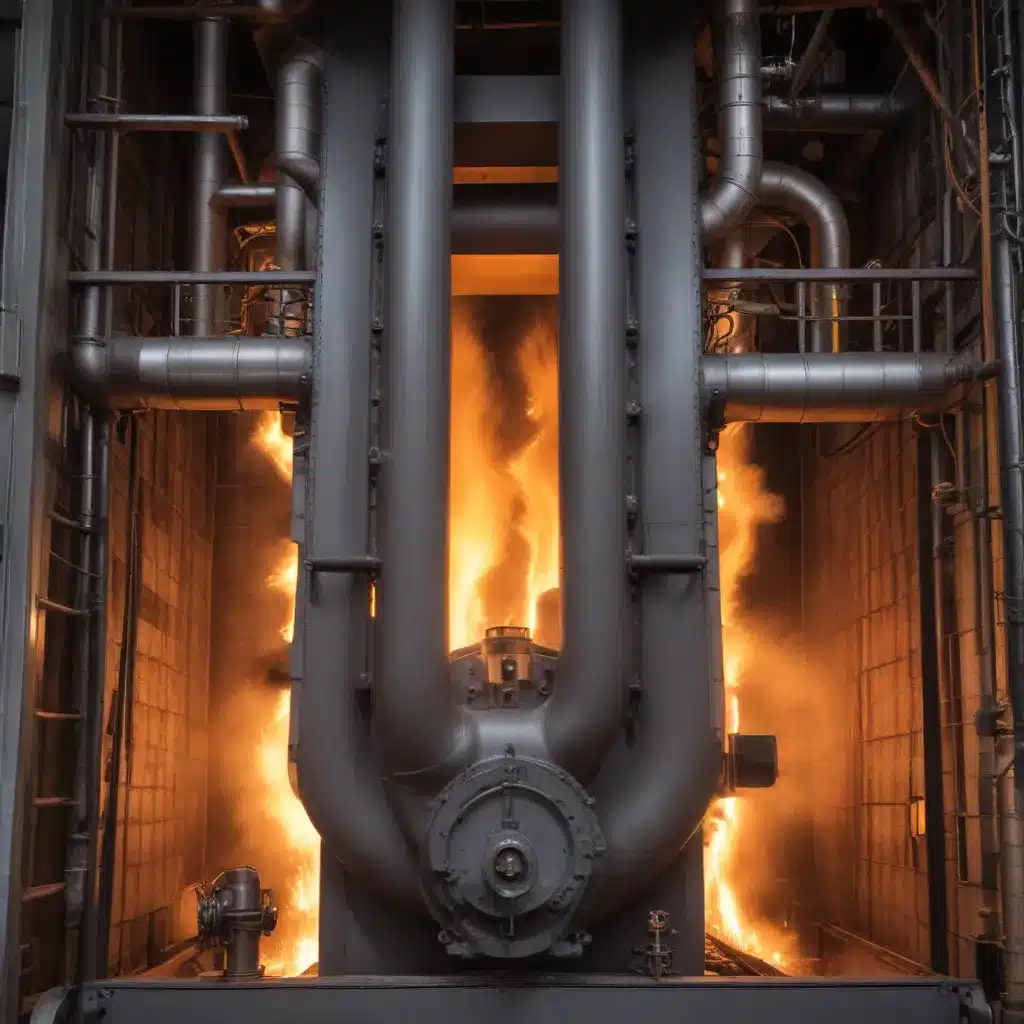

At the heart of every boiler lies a complex combustion process, where fuel is burned to generate heat and steam. Achieving optimal combustion is essential for getting the most out of your boiler system. This process involves carefully balancing the air-to-fuel ratio, ensuring complete and efficient fuel burning while minimizing the formation of harmful byproducts.

Improper combustion can lead to a host of issues, including:

- Reduced Efficiency: When the air-to-fuel ratio is off, the boiler cannot convert fuel into heat energy as effectively, resulting in higher fuel consumption and increased operating costs.

- Increased Emissions: Incomplete combustion can lead to the release of pollutants, such as carbon monoxide (CO) and nitrous oxides (NOx), posing environmental and health concerns.

- Shortened Lifespan: Inefficient combustion can cause premature wear and tear on boiler components, leading to more frequent breakdowns and a shorter overall lifespan for the system.

By optimizing the boiler’s combustion process, you can unlock a range of benefits, including:

- Enhanced Efficiency: Ensuring the perfect air-to-fuel ratio can dramatically improve the boiler’s fuel-to-steam conversion, reducing energy consumption and operating costs.

- Improved Safety: Proper combustion optimization helps prevent the buildup of dangerous byproducts, such as carbon monoxide, safeguarding your home or facility.

- Increased Reliability: Well-maintained and optimized boiler combustion systems are less prone to breakdowns, ensuring consistent and dependable heating performance.

- Extended Lifespan: Optimized combustion helps extend the overall lifespan of your boiler, maximizing your investment and reducing the need for frequent replacements.

Strategies for Boiler Combustion Optimization

Achieving optimal boiler combustion requires a multifaceted approach, incorporating both preventive maintenance and advanced control technologies. Let’s explore some of the key strategies:

Preventive Maintenance

Regular maintenance is the foundation for ensuring efficient and safe boiler combustion. This includes:

- Periodic Cleaning: Removing soot, scale, and other deposits from the boiler’s heat exchanger, burners, and other critical components can improve airflow, fuel-to-heat conversion, and overall efficiency.

- Flame Monitoring: Regularly inspecting the boiler’s flame pattern and appearance can help identify any issues with the combustion process, such as incomplete burning or excess air intake.

- Sensor Calibration: Ensuring that the boiler’s oxygen (O2) and carbon monoxide (CO) sensors are properly calibrated helps maintain accurate readings, enabling fine-tuning of the air-to-fuel ratio.

- Burner Adjustments: Periodically adjusting the burner settings, including air intake and fuel flow, can help optimize the combustion process and maintain peak efficiency.

Advanced Combustion Control Systems

The latest generation of boiler control systems offers sophisticated combustion optimization capabilities, leveraging cutting-edge technologies to enhance performance and safety. Some key features include:

- Real-Time Monitoring: Advanced control systems can continuously monitor critical combustion parameters, such as oxygen levels, CO emissions, and fuel-to-air ratios, enabling instant adjustments to maintain optimal conditions.

- Automated Adjustments: Intelligent control algorithms can automatically adjust the air-to-fuel ratio, combustion air flow, and other variables to ensure efficient and clean burning, even as conditions change.

- Predictive Maintenance: By analyzing combustion data trends, these control systems can identify potential issues before they lead to breakdowns, allowing for proactive maintenance and minimizing unplanned downtime.

- Emissions Reduction: Advanced combustion controls can precisely manage the fuel-to-air ratio, minimizing the formation of harmful pollutants like nitrogen oxides (NOx) and carbon monoxide (CO), contributing to a cleaner, more environmentally-friendly operation.

Boiler Upgrades and Modernization

In some cases, upgrading or modernizing an older boiler system can be the most effective way to optimize combustion performance and safety. This may include:

- Burner Replacement: Upgrading to a more efficient and advanced burner can significantly improve the combustion process, reducing fuel consumption and emissions.

- Control System Upgrades: Integrating state-of-the-art combustion control technologies can enhance monitoring, adjustment capabilities, and overall system optimization.

- Heat Exchanger Improvements: Replacing or enhancing the boiler’s heat exchanger can increase heat transfer efficiency, further boosting overall system performance.

By combining preventive maintenance, advanced control systems, and targeted boiler upgrades, you can achieve optimal combustion, maximize energy efficiency, and ensure the long-term safety and reliability of your heating systems.

The Importance of Boiler Safety

Boiler safety is paramount, as these powerful appliances can pose serious risks if not properly maintained and operated. Unsafe conditions can lead to catastrophic failures, fires, explosions, and the release of toxic gases, such as carbon monoxide, which can have devastating consequences.

To ensure the utmost safety, it’s crucial to adhere to industry standards and regulations, and implement comprehensive safety features, including:

- Pressure Relief Valves: These critical safety devices are designed to automatically release excess pressure, preventing dangerous overpressure situations.

- Low-Water Cutoffs: This safety feature monitors the boiler’s water level, automatically shutting down the system if the level drops too low to prevent damage.

- Flame Monitoring: Advanced control systems can constantly monitor the boiler’s flame, automatically shutting down the system if any irregularities are detected.

- Ventilation and Exhaust Systems: Proper ventilation and exhaust systems are essential for ensuring the safe and efficient removal of combustion byproducts, such as carbon monoxide.

In addition to these safety features, regular maintenance, operator training, and adherence to local codes and regulations are crucial for maintaining a safe and reliable boiler system.

Boiler Applications Across Industries

Boilers are essential components in a wide range of industrial, commercial, and institutional settings, serving diverse applications that rely on the generation of heat and steam. Let’s explore some of the key industries and applications that benefit from boiler combustion optimization:

- Manufacturing: Boilers are extensively used in manufacturing processes, providing heat for various operations, such as cleaning, drying, and powering machinery.

- Chemical Production: In the chemical industry, boilers are vital for heating, distillation, reaction heating, and finished product drying.

- Food Processing: Boilers play a crucial role in ensuring food safety through sterilization and pasteurization processes.

- Pharmaceuticals: Boilers are essential for creating the sterile environments required for pharmaceutical equipment and product manufacturing.

- Oil and Gas: In the oil and gas industry, boilers generate the hot water and steam needed for drilling operations and power generation.

- Commercial and Institutional Applications: Boilers are widely used in buildings, on college campuses, and in the hospitality industry, providing heating and hot water for various needs.

Optimizing the combustion performance of boilers in these diverse settings can yield significant benefits, including improved energy efficiency, reduced operating costs, enhanced safety, and better environmental sustainability.

Conclusion: Unlocking the Full Potential of Your Boiler System

Boiler combustion optimization is a critical aspect of maintaining efficient, safe, and reliable heating systems. By incorporating preventive maintenance, advanced control technologies, and strategic boiler upgrades, you can unlock the full potential of your boiler, ensuring optimal performance, extended lifespan, and the highest levels of safety for your home, facility, or industrial operation.

As a seasoned expert in plumbing and heating services, I encourage you to explore the strategies and insights outlined in this comprehensive guide. By taking a proactive approach to boiler combustion optimization, you can not only enhance the performance of your heating systems but also contribute to a more sustainable and energy-efficient future.

For more information or to explore customized solutions for your specific needs, please visit https://ddplumbingandheating.co.uk/. Our team of experienced professionals is dedicated to helping you achieve the best possible results for your boiler systems and heating requirements.