Mastering the Art of Boiler Combustion Monitoring

Boilers are the unsung heroes powering countless industries, silently delivering the steam and heat that drive essential processes. But beneath their robust exteriors lies a symphony of carefully orchestrated components, each playing a vital role in ensuring safe and efficient operation. At the heart of this intricate system lies the art of boiler combustion monitoring – a disciplined practice that maintains the delicate balance between power and precision.

As seasoned experts in plumbing and heating services, we understand the critical importance of combustion monitoring in boiler systems. By closely observing and managing the combustion process, we can unlock the true potential of these workhorses, optimizing their performance while safeguarding the well-being of both people and equipment.

In this comprehensive guide, we’ll delve into the world of boiler combustion monitoring, exploring the advanced technologies, safety protocols, and industry-leading best practices that ensure your boiler systems operate at the peak of efficiency and reliability. Whether you’re responsible for a large-scale industrial facility or maintaining a residential heating system, this in-depth exploration will equip you with the knowledge and confidence to master the art of boiler combustion monitoring.

The Fundamentals of Boiler Combustion Monitoring

At the core of boiler operation lies the combustion process – the controlled burning of fuel to generate heat energy. This heat is then transferred to water, transforming it into steam that can be harnessed for a multitude of industrial and commercial applications. Effective combustion monitoring is the key to unlocking the full potential of this process, ensuring that fuel is consumed efficiently while mitigating the risks associated with boiler operation.

Monitoring Combustion Parameters

Successful combustion monitoring revolves around the precise measurement and control of critical parameters, including:

-

Fuel-to-Air Ratio: Maintaining the optimal balance between fuel and air supply is crucial for complete and efficient combustion. Monitoring this ratio ensures optimal energy transfer and minimizes the formation of harmful emissions.

-

Excess Oxygen Levels: Carefully monitoring the amount of excess oxygen present in the combustion chamber helps prevent incomplete combustion, which can lead to reduced efficiency and the production of pollutants.

-

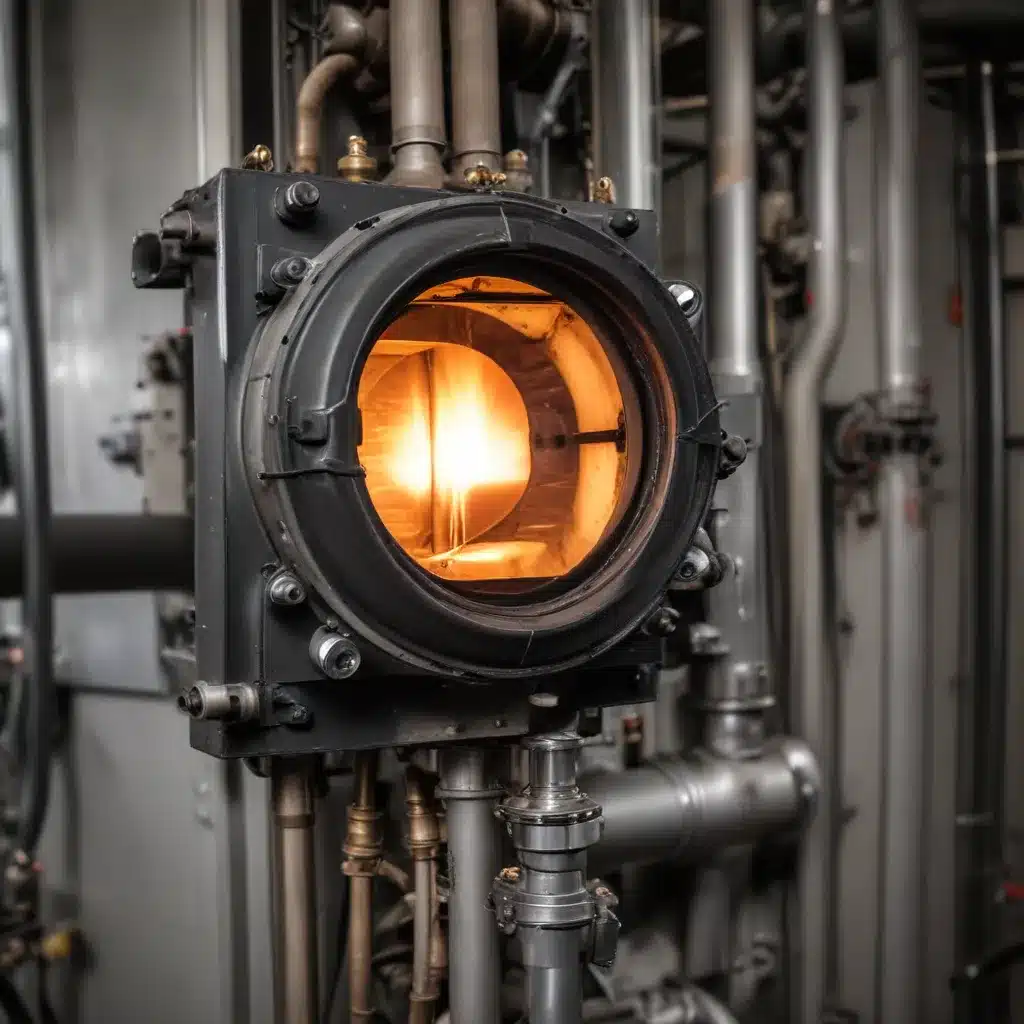

Flame Stability and Visibility: Observing the flame characteristics, such as color, shape, and consistency, provides valuable insights into the combustion process. Stable, visible flames indicate efficient and safe operation.

-

Exhaust Gas Composition: Analyzing the composition of the exhaust gases, including the levels of carbon monoxide (CO), carbon dioxide (CO2), and nitrogen oxides (NOx), helps identify any potential issues with the combustion process.

By closely tracking these critical parameters, boiler operators and maintenance professionals can make informed decisions, adjust operating conditions, and implement corrective measures to ensure the system runs at peak efficiency and safety.

Advanced Combustion Monitoring Technologies

To enhance the precision and reliability of boiler combustion monitoring, modern systems incorporate a range of advanced technologies, including:

-

Oxygen Sensors: These sensors continuously measure the oxygen content in the exhaust gases, providing real-time feedback on the fuel-to-air ratio to maintain optimal combustion efficiency.

-

Infrared (IR) and Ultraviolet (UV) Flame Detectors: These specialized sensors monitor the flame characteristics, detecting any fluctuations or instabilities that could indicate potential problems.

-

Flue Gas Analyzers: Sophisticated analyzers measure the composition of the exhaust gases, allowing operators to identify and address issues related to incomplete combustion or excessive emissions.

-

Programmable Logic Controllers (PLCs): Integrated control systems continuously monitor and adjust boiler operations based on the data collected from various sensors, ensuring precise and responsive combustion management.

By leveraging these advanced technologies, boiler operators can maintain a comprehensive understanding of the combustion process, enabling them to make informed decisions, optimize system performance, and safeguard the overall integrity of the boiler.

Ensuring Safe and Efficient Boiler Operation

Combustion monitoring is not just about optimizing efficiency; it is also a critical component of boiler safety. Neglecting this essential practice can lead to catastrophic consequences, putting both personnel and equipment at risk. As such, a robust safety culture and a deep understanding of boiler safety protocols are paramount.

Maintaining Safe Operating Limits

Boilers operate under extreme conditions, with elevated temperatures and pressures that demand strict adherence to safety guidelines. Combustion monitoring plays a pivotal role in ensuring that these critical parameters remain within their safe operating limits. By continuously tracking pressure, temperature, and other key indicators, operators can swiftly detect and address any deviations that could compromise the system’s integrity.

Safeguarding Against Hazardous Conditions

Proper combustion monitoring also serves as a vital line of defense against hazardous conditions that can arise within the boiler system. This includes the timely detection of:

-

Fuel Supply Issues: Disruptions in the fuel supply, such as blockages or leaks, can lead to incomplete combustion and the potential for explosions or fires.

-

Flame Instability: Fluctuations in the flame characteristics can indicate the presence of air-fuel ratio imbalances, which can result in dangerous flare-ups or pulsations.

-

Excess Emissions: High levels of pollutants like carbon monoxide and nitrogen oxides can pose serious health risks to personnel and the environment if left unchecked.

By proactively monitoring these critical factors, boiler operators can swiftly intervene and implement corrective measures, minimizing the risk of catastrophic failures and safeguarding the well-being of all.

Comprehensive Safety Protocols

Ensuring the safe operation of boiler systems requires a comprehensive approach that goes beyond just combustion monitoring. A robust safety protocol should encompass the following elements:

-

Thorough Inspections: Regular inspections of all boiler components, including pressure vessels, safety valves, and control systems, are essential for identifying and addressing potential issues before they escalate.

-

Maintenance and Servicing: Adhering to a rigorous maintenance schedule, performed by qualified technicians, helps maintain the boiler’s optimal condition and prevent the buildup of issues that could compromise safety.

-

Emergency Preparedness: Detailed emergency response plans, regular training, and the availability of appropriate personal protective equipment (PPE) are crucial for mitigating the impact of boiler-related incidents.

-

Regulatory Compliance: Staying up to date with local, regional, and national boiler safety regulations, and ensuring full compliance, is a non-negotiable requirement for safe and responsible boiler operation.

By seamlessly integrating combustion monitoring into a comprehensive safety framework, boiler operators can cultivate a culture of safety that safeguards both personnel and the integrity of the equipment.

Optimizing Boiler Efficiency Through Combustion Monitoring

While safety is paramount, the benefits of effective combustion monitoring extend far beyond risk mitigation. By closely monitoring and managing the combustion process, boiler operators can unlock substantial improvements in system efficiency, delivering tangible cost savings and environmental benefits.

Enhancing Fuel Utilization

Precise combustion monitoring allows for the optimization of the fuel-to-air ratio, ensuring that the fuel is consumed as completely and efficiently as possible. By maintaining the ideal balance, boiler systems can minimize fuel wastage and maximize the energy output, resulting in significant cost savings on fuel expenditure.

Reducing Emissions and Environmental Impact

Effective combustion monitoring plays a crucial role in minimizing the environmental impact of boiler operations. By closely monitoring and controlling the levels of pollutants such as nitrogen oxides, sulfur oxides, and particulate matter in the exhaust gases, boiler operators can implement measures to reduce harmful emissions, contributing to better air quality and compliance with increasingly stringent environmental regulations.

Extending Equipment Lifespan

Optimized combustion processes not only enhance efficiency but also contribute to the longevity of boiler equipment. By preventing issues like corrosion, scaling, and thermal stress, which can arise from suboptimal combustion, boiler operators can extend the useful life of their systems, deferring costly replacements or major overhauls.

Improving Reliability and Uptime

Consistent combustion monitoring and timely adjustments to the boiler’s operating parameters help maintain a stable and reliable system. This, in turn, reduces the likelihood of unexpected breakdowns or unscheduled downtime, ensuring a consistent supply of steam or hot water for mission-critical industrial processes and commercial applications.

By embracing the power of combustion monitoring, boiler operators can unlock a trifecta of benefits: enhanced efficiency, reduced environmental impact, and improved system reliability – all of which translate into tangible cost savings and a stronger competitive edge.

Boiler Combustion Monitoring in Action: Industry Applications

Boiler combustion monitoring is a critical component across a diverse array of industries, each with its unique operational requirements and challenges. Let’s explore how this discipline manifests in some of the key sectors that rely on the consistent and reliable performance of boiler systems.

Power Generation

In power generation plants, boiler combustion monitoring is paramount to ensuring the efficient and safe operation of steam-powered turbines. By maintaining precise control over the combustion process, operators can optimize fuel consumption, reduce emissions, and maximize the output of electrical power. Continuous monitoring of parameters like oxygen levels, flue gas composition, and flame stability allows power plant personnel to swiftly address any deviations and maintain a consistent, reliable energy supply.

Industrial Manufacturing

Across a wide range of manufacturing industries, from pharmaceuticals to food processing, boiler systems are essential for powering critical processes like heating, sterilization, and drying. Combustion monitoring in these environments is crucial, as it enables manufacturers to maintain strict quality standards, optimize energy usage, and comply with stringent safety and environmental regulations. By closely monitoring combustion parameters, operators can ensure consistent, high-quality outputs while minimizing operational disruptions.

Commercial Heating and Comfort

In the commercial sector, boiler systems are the backbone of heating systems that provide comfort and well-being for occupants of buildings, from offices to hospitals. Effective combustion monitoring in these applications ensures the reliable and efficient delivery of heat, maintaining a comfortable indoor environment while minimizing energy consumption and operating costs. By staying attuned to combustion performance, facility managers can proactively address issues and optimize the overall heating system’s operation.

Regardless of the industry, the principles of boiler combustion monitoring remain consistent: ensuring safety, maximizing efficiency, and maintaining the integrity of these critical systems. By embracing a comprehensive approach to combustion monitoring, organizations can unlock tangible benefits that translate into improved operational performance, cost savings, and environmental sustainability.

Mastering Boiler Combustion Monitoring: A Roadmap to Success

Achieving excellence in boiler combustion monitoring requires a multi-faceted approach that combines technical expertise, operational best practices, and a commitment to continuous improvement. As seasoned professionals in the plumbing and heating industry, we have developed a proven roadmap to help organizations navigate the complexities of this discipline and realize its full potential.

Invest in Advanced Monitoring Technologies

Equipping your boiler systems with the latest combustion monitoring technologies is the foundation for success. Embrace solutions that provide real-time data on critical parameters, enable remote access and diagnostics, and seamlessly integrate with your control systems. By leveraging the power of advanced sensors, analytics, and automation, you can elevate your combustion monitoring capabilities and make more informed, data-driven decisions.

Implement Robust Maintenance and Inspection Protocols

Consistent maintenance and thorough inspections are essential for maintaining the optimal performance and safety of your boiler systems. Develop a comprehensive maintenance plan that covers all critical components, from burners and heat exchangers to safety valves and control systems. Enlist the expertise of qualified technicians to perform regular servicing and identify potential issues before they escalate, ensuring your boiler systems operate at peak efficiency and reliability.

Foster a Culture of Safety and Continuous Improvement

Cultivating a strong safety culture is paramount in the world of boiler operations. Empower your team with comprehensive training on safe operating procedures, emergency response protocols, and the importance of combustion monitoring. Encourage a mindset of continuous learning and improvement, where personnel are empowered to identify optimization opportunities and implement innovative solutions.

Leverage Data-Driven Insights

Harness the power of data-driven decision-making to optimize your boiler combustion monitoring strategies. Meticulously track and analyze performance metrics, emission levels, and energy consumption patterns to uncover optimization opportunities. Use this data to fine-tune your combustion parameters, implement targeted efficiency improvements, and demonstrate the tangible impact of your efforts to key stakeholders.

Maintain Compliance with Evolving Regulations

Stay vigilant in your efforts to keep pace with the ever-changing regulatory landscape surrounding boiler operations and emissions. Actively monitor updates to local, regional, and national guidelines, and ensure your combustion monitoring practices and equipment adhere to the latest standards. Proactive compliance not only safeguards your organization but also positions you as an industry leader committed to responsible and sustainable boiler management.

By embracing this comprehensive roadmap, you can elevate your boiler combustion monitoring capabilities, ensure the safety and reliability of your systems, and unlock substantial operational and financial benefits for your organization. Remember, mastering this discipline is an ongoing journey, but one that is well worth the investment.

Unlock the Full Potential of Your Boiler Systems with DD Plumbing and Heating

At DD Plumbing and Heating, we are dedicated to empowering our clients with the knowledge and tools necessary to optimize the performance and safety of their boiler systems. As seasoned experts in the plumbing and heating industry, we have honed our expertise in combustion monitoring, enabling us to provide tailored solutions and guidance that address the unique challenges faced by organizations across a diverse range of sectors.

Whether you’re responsible for a power generation facility, a manufacturing plant, or a commercial heating system, our team of professionals is here to help you navigate the complexities of boiler combustion monitoring. From the installation and integration of advanced monitoring technologies to the development of comprehensive maintenance protocols and safety procedures, we are committed to equipping you with the knowledge and resources necessary to unlock the full potential of your boiler systems.

Unlock the benefits of enhanced efficiency, improved reliability, and reduced environmental impact by partnering with DD Plumbing and Heating. Contact us today at https://ddplumbingandheating.co.uk/ to schedule a consultation and take the first step towards mastering the art of boiler combustion monitoring.